Amorphous Ribbons and Components

Amorphous alloy is a new type of energy saving material produced by rapid solidification technology, being cooled from molten alloy at a rate of nearly million degrees per second. It has high permeability and low core loss because of the unique long-range disordered atomic structure, which is completely different from that of crystals. Amorphous alloy is widely used in the fields of distribution transformers, inductors, motor stators and sensors, taking the advantage of significantly improving device efficiency and reducing energy consumption.

Features

The below characteristics of the iron-based amorphous alloys lead to ultra low core loss.

Thinner thickness —1/10 of CRGO;

Higher electrical resistance — two times higher than CRGO;

Lower coercive force —1/3 of CRGO.

The magnetic devices made with iron-based amorphous alloy could be operated at higher working induction with excellent anti-saturate ability and smaller size, due to the highest saturation induction among all amorphous alloys.

3 tailored products of low core loss (AN101), excellent overload tolerance (AN101S), and high saturation (AN101A) could be provided, according to customer's different requirements.

Typical Applications

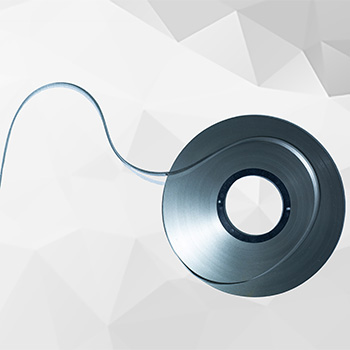

Magnetic shielding sheets are mainly used for EMI resistance, electromagnetic screens, NFC and wireless charging of various electronic products.