Nanocrystalline Components

Dedicated to developing ultra-thin ribbons with various magnetic properties, AT&M promotes the development of electronic equipment towards the direction of high frequency and miniaturization. Antainano® common mode chokes (CMC)based on ultra-thin ribbon offer high impedance in compact designs for a wide range of EMI requirements.

Antainano® high frequency power transformer (HFPT) use Antainano® ONL series core which has high saturation flux density, low core loss and near-zero magnetostriction. Those products allow reduction in size and weight, and low energy loss for your applications.

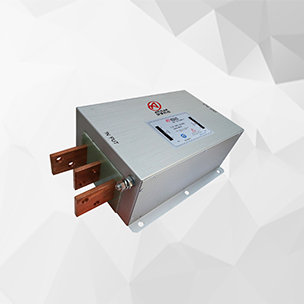

Antainano® EMI filter can provide one-stop EMC services in terms of EMC test, design, on-site improvement and system solutions, etc.

Features

Compared with traditional ferrite, nanocrystalline component is characterized with the following benefits when applied in high frequency power supply (below 100 kHz). It has the benefits of small volume, low temperature rise, efficient high temperature conversion, good anti-unbalanced current characteristics and small fluctuation of high temperature input impedance, etc. Moreover, it possesses obvious advantage in solving the EMC problem of the circuit.

Typical Applications

Typical applications are as below:

• Common Mode Choke Cores (CMC Cores)

Common Mode Chokes (CMCs) are widely used in variable frequency air conditioner, radiant cooker, solar energy, wind power, EV/PHEV, inverter welding machine and other fields.

• High Frequency Power Transformer Cores (HFPT Cores)

High frequency power transformers (HFPTs) are widely used in switching power supply in various fields, such as railway transportation, electric vehicles, tram chargers, switching power supply on ships, communication power supply, welding and electroplating power supply, radio and TV transmitter power supply, wind power supply, NMR chromatography X ray camera, particle accelerator lightweight, etc.