Nanocrystalline Cores

Nanocrystalline cores can be classified as Common Mode Choke Cores (CMC), High Frequency Power Transformer Cores (HFPT) and Current Transformer Cores (CT) based on different uses and performances.

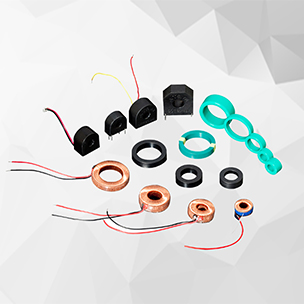

According to the magnetic properties of cores, selecting suitable compositions, the nanocrystalline ribbon is wound into cores of various shapes and sizes, such as toroidal, rectangular, C-shape or E-shape, etc. After specific heat treatment process, cores with required magnetic properties will be produced and encapsulated in accordance with customers requirements.

Features

Compared with ferrite, nanocrystalline has higher Curie temperature, wide working temperature range and excellent thermal stability. It has higher magnetic permeability and higher saturation flux density, which can significantly reduce the volume and weight of cores. Therefore, it is more compatible with the development trend of miniaturization and lightweight of electronic products.

Typical Applications

Typical applications are as below:

Common Mode Choke Cores (CMC Cores)

Nanocrystalline common mode choke core has excellent frequency and impedance characteristics, which makes it the state-of-the-art material for a wide range of applications, e.g. power supply, electric drive and electric control systems for electric vehicles, photovoltaic power inverters, wind power converters, switching power supply for home appliances, as well as EMC solutions of industrial power supplies such as inverter welding machine.

High Frequency Power Transformer Cores (HFPT Cores)

Nanocrystalline Power transformer cores are widely used in various high-frequency industrial power supplies. For example, nanocrystalline toroidal cores are mainly used in inverter welding machine power supply, induction heating equipment power supply, communication power supply, UPS power supply, X-ray machine power supply, laser power supply, variable-frequency power supply, etc. As for nanocrystalline rectangular and C-shape cores, they are mainly used in electric locomotive traction/auxiliary power supplies, DC converters, electrostatic precipitating power supplies, etc.

Current Transformer Cores (CT Cores)

Nanocrystalline current transformer cores are mainly used in electric power transmission, electronic watt hour meters, and leakage protection switches, etc.